- Home

- Software & Support

- Consulting & Services

- ResourcesBest practicesPractical guidesWhite papersVideosBlogBest practicesPractical guidesWhite papersVideosBlog

- Research

- About Us

- Contact

Sensory testing is a valuable risk management tool that can prevent companies from experiencing product disasters and help inform new product development. Sensory and consumer methodologies can be applied to achieve a myriad of objectives, including:

The test must be properly designed to obtain reliable and robust outcomes.

In sensory testing, the most common source of bias is the order effect. The first sample we see or taste is perceived differently because it’s a fresh experience. When we get the second sample, we have the first sample’s impact influencing our response.

The experimental design, that is the order of sample presentation, can be rotated and balanced to ensure that all samples are treated in the same manner and that the test is fair. If we insert a warm-up sample at the start of each sample set that is neither evaluated nor measured, then the effect is equal for all samples in the test.

In sensory testing, the most common source of bias is the effect of order of sample evaluation. The first sample we see or taste is perceived differently because it’s a fresh experience. When we get the second sample, we have the first sample’s impact influencing our response.

The experimental design, that is the order of sample presentation, can be rotated and balanced to ensure that all samples are treated in the same manner and that the test is fair. If we insert a warm-up sample at the start of each sample set that is neither evaluated nor measured, then the effect is equal for all samples in the test.

If we have too many samples to evaluate in one sitting, we can use sessions to manage our study. The large complete block design (CBD) can be sliced into columns and a limited number of columns may be presented in each sitting. This way the whole block can be evaluated over several days, or even weeks if the samples are sufficiently stable to permit doing so.

We can also opt for balanced incomplete block (BIB) designs that ensure that all samples are seen equally, but no one sees all the samples. The size of the block is based upon what an assessor can manage to evaluate in one session without compromising data quality by fatigue or carry-over. It is possible to balance blocks over sessions to have all samples seen by each panelist.

This BIB technique begins with determining the sensory profiles of the products through descriptive analysis. We ensure that the products chosen cover the sensory space, the range of attributes and their intensities, of the product category. The incomplete blocks are made using products that have a sensory contrast and can be used to cluster our consumers on their liking response.

Out of 16 possible products, consumers have only conducted SID category appraisals on 6. This approach cuts the cost of these studies in half and delivers excellent products development guidance.

When a loyal consumer experiences your product, they consider it to be their own product. Iconic brands must deliver with consumer expectations in mind, or risk breaking faith with their core customers.

In the 1980s, Marks & Spencer introduced sensory specification into their private label purchasing process. To this day, leading retailers rely on their private label suppliers to establish sensory specifications that move beyond consumer liking to a standard of brand identity that defines the product.

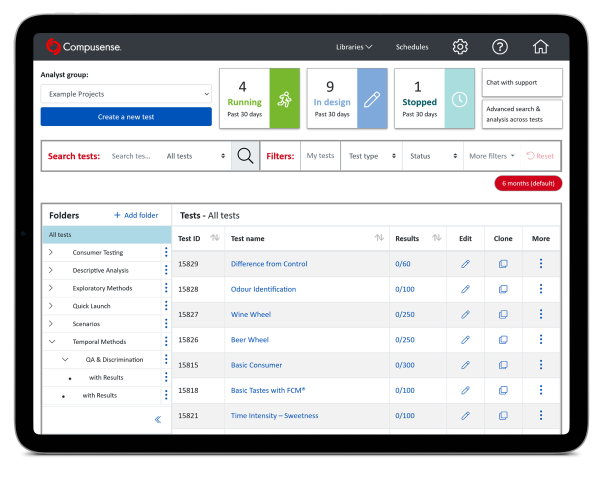

The main sensory analysis tool that helps us define sensory properties objectively is descriptive analysis. The proprietary Compusense Feedback Calibration, also referred to as FCM®, was introduced in 2003 and has become the most efficient and effective method for training and maintaining proficient descriptive analysis panels.

By using immediate feedback to train panelists, it takes as little as two sessions to train panelists with individual onscreen guidance. Panelists input their responses to specific attributes using a series of line scales. Each screen displays their response in comparison to an established range. The feedback is immediate and accurate in identifying how close their response was to the target.

The immediacy of the feedback acts as reinforcement, subsequently expediting panelists’ learning and calibrating their responses to the target ranges. FCM® provides an effective method for training descriptive sensory panels to a high proficiency. These definitive profiles will help you guide all new development and future expansions objectively.

Consumer testing provides confidence in your product and the quality of data from testing is dependent on getting the recruit right in the first place. A well-recruited database of 5000+ consumers provides a solid base for selection of panelists. Typically, consumer panels are comprised of 100 category or brand consumers. Using antiquated methods, 100 panelists would require up to 60 hours of recruitment, interviewing, selecting and scheduling.

Online screening, using Compusense, is the first step in qualifying respondents that meet the test’s demographic quotas. By using quotas, only as many consumers as necessary will complete the test, keeping costs and the number of required samples down. Qualified consumers are then able to immediately book their own time slot to participate in the product test using the scheduling tool. If for some reason a panelist can no longer make their original appointment, individuals can return and reschedule themselves in a new time slot.

Using Compusense, recruitment, screening and scheduling of 100 panelists can be completed in less than two hours, translating into a 97 per cent reduction in labour. This approach results in saving the equivalent of about two weeks of work and knocks a week off the project timeline. The Compusense approach to recruiting and scheduling can save thousands of dollars and deliver results in half the time.

We recognize the important role that best practices play in driving positive outcomes within sensory testing and evaluation. Discover how you can integrate consumer testing with Compusense’s recruitment and scheduling.

Email: info@compusense.com

1 800 367 6666 (North America)

1 519 836 9993 (International)

412 Laird Road Unit #104

Guelph, ON

Canada N1G 3X7

© 2024 Copyright Compusense Inc.

412 Laird Road, Unit #104

Guelph, ON

Canada N1G 3X7

© 2024 Copyright Compusense

Quality test methods are used to evaluate a product based on its sensory attributes and overall consumer perception to ensure it meets certain standards of excellence and consistency. These methods provide a consumer-centric assessment of product quality, ensure consistency and adherence to quality standards and drive continuous improvement and customer satisfaction. Examples include, but are not limited to, Shelf Life, Degree of Difference,

Difference from Control, In/Out, etc.

Quality test methods are used to evaluate a product based on its key attributes to ensure it meets specific standards of excellence for consistency. These methods provide an internal assessment of the product quality to adhere to quality standards and achieve customer satisfaction. Examples include, but are not limited to, Shelf-Life, Degree of Difference, Difference from Control, and In & Out methods.

Discrimination test methods are used to determine if there are noticeable differences or similarities between products. These methods enable effective differentiation between products, aid in quality control and assurance by identifying variations and deviations, as well as facilitate efficient decision-making based on objective data. Examples include, but are not limited to, Tetrad, Triangle, Duo-Trio, Paired Comparison, etc.

Discrimination testing methods are used to determine if there are noticeable differences or similarities between products. These methods enable effective differentiation between products, aid in quality control and assurance by identifying variations and deviations, as well as facilitate efficient decision-making based on objective data. Examples include, but are not limited to, Tetrad, Triangle, Duo-Trio, and Paired Comparison test methods.

Quality test methods are used to evaluate a product based on its sensory attributes and overall consumer perception to ensure it meets certain standards of excellence and consistency. These methods provide a consumer-centric assessment of product quality, ensure consistency and adherence to quality standards and drive continuous improvement and customer satisfaction. Examples include, but are not limited to, Shelf Life, Degree of Difference,

Difference from Control, In/Out, etc.

Quality test methods are used to evaluate a product based on its key attributes to ensure it meets specific standards of excellence for consistency. These methods provide an internal assessment of the product quality to adhere to quality standards and achieve customer satisfaction. Examples include, but are not limited to, Shelf-Life, Degree of Difference, Difference from Control, and In & Out methods.